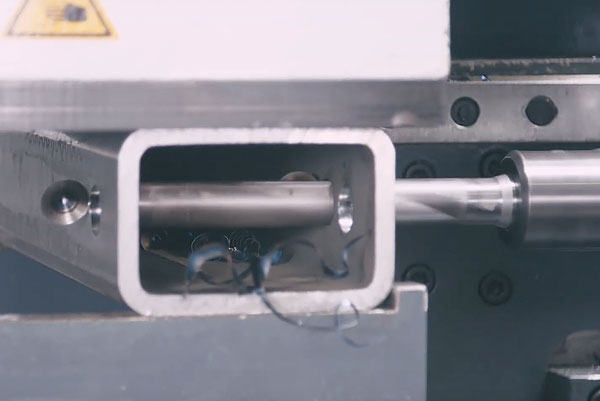

A CNC drill line is useless if it does not position a fabricator for success in the steel fabrication industry. The Advantage-2 can process technical programs quickly and with intelligence. Each drilling axis is equipped with three five-station tool changers. They can drill, mill countersink tap, tap, and scribe. You can also equip this drill line with a Signoscript underside Scriber or Signomat Part Stamping Unit. Even after blasting, painting, and galvanizing, part information can be retained. Minimizing shop errors? Check. Check. High torque drilling axes feature a thicker, more aggressive cut that removes more chips with every rotation. This drill line can chew through beams and tube, channel, angle, tube, and flat bars. Advantage-2 has a processing window that measures 44 inches in width and 18 inches high.

Voortman has developed Raptor 3DCAD/CAM Software. This software takes CNC innovation one step further. Users can program faster and more accurately with Raptor 3DCAD/CAM Software. You can inspect, modify and export your part information from within the 3D platform. This combination with Voortman CNC technology ensures maximum capacity for fabricators.